Implementing Six Sigma in a Software company

Six Sigma has become very popular in the last many years. But implementing it in a Software company or a project is still dealt with some resistance.

In this article let us try to understand Six sigma, it's benefits and strategies for implementing it in a company or project.

What is Six Sigma?

Six Sigma is a series of methods adopted to improve products, services or processes. It indicates the number of standard deviation with respect to customer expectations.

It takes into account performance measure and business improvement to reduce the number of defects

Sigma (Greek) – means standard deviation (measure of variation) of a population of data

The sigma measure (σ) is the standard deviation which is an indication of the amount of variation or inconsistency in a process. Six sigma is one in which 99.99966% of the products manufactured are expected to be free of defects (3.4 defects per million)

Managing Up the Sigma Scale

|

Sigma |

% Good |

% Bad |

Defects per million opportunities (DPMO) |

|

1 |

30.9% |

69.1% |

691,462 |

|

2 |

69.1% |

30.9% |

308,538 |

|

3 |

93.3% |

6.7% |

66,807 |

|

4 |

99.38% |

0.62% |

6,210 |

|

5 |

99.977% |

0.023% |

233 |

|

6 |

99.9997% |

0.00034% |

3.4 |

|

7 |

99.9999981% |

0.0000019% |

0.019 |

Benefits of following six sigma

Companies which maintain their process in six sigma can definitely see the impact of quality. This have an effect on the sales of the organization.

Also the amount of re-work will reduce considerably which will affect the cost.

Fears about Six Sigma:

There is a general belief that Six Sigma is not applicable to service companies, it’s expensive to implement and a fear that Six sigma might turn out to be a fad.

Software vs Manufacturing process

Six Sigm was actually designed for manufacturing process. And there are various reasons which make a Software process very different from manufacturing processes.

| # | Software | Manufacturing |

|

1

2

3 |

There's no physical existence

Impacted by programming skills, level of expertise and knowledge

Change in Project requirements |

Physical existence of the products

Impacted by temperature, humidity, human interaction, degradation of machine performance

Production starts once all the process is frozen |

Software development processes are characterized by 3 simple measurements

Time:

The time required to perform a specific task

Size

The size of the product produced

Defects

The number and type of defects, time to eliminate defects

Key parameters for service companies

Following are few important factors that stand out for companies in a service focused environment:

Service defections (lost customers):

Unsatisfied Customers will switch to another service provider

Customer satisfaction ratings:

Measure how customers define value and build internal processes. This will result in greater customer loyalty and longer-term company profitability

Service turnaround times:

Ability to handle customers’ needs within the timelines will serve in achieving long standing relationship

Benefits of service-oriented businesses adopting Six Sigma

Entire organization can visualize the improved cross-functional teamwork. Organizational culture changes from being reactive to proactive.

The number of non-value steps can be reduced in the entire business process to provide fast delivery of service. Reduced costs associated with late delivery and customer complaints.

Service level offered to clients will improve with reduction in variance. Effectiveness of management decisions will improve with reliance on data and facts

Strategies for adopting Six Sigma

The strategy of successful six sigma implementation starts with convincing the stakeholders and ends with defining the success of the project

Critical Success of Six sigma depends on below mentioned factors

Management & Functional Component

Management Component:

- Selecting the right people for six sigma deployment

- Selecting right training, process methods and clear direction

Functional Component

- Improving the process by reducing variation

- Solving problems using statistical tools and techniques

Client Component

If you have customers, then it becomes important that you include this component also.

- Convince the clients that Six Sigma is not a fad

- Less use of complex jargons

- Low price is not low cost

- Positioning six sigma as not a expense activity but as a revenue generating activity

- Illustrating case study on Industry best practices and their potential impacts

- Adopting required changes necessary for clients

- Success metrics can be tailored like measuring Six Sigma value in terms of a percentage of revenue, profitability, new business opportunities, etc

- Measure the Key Success Indicators to define the success of the project

- Preparing case study on the project which can be used for future references

Positioning to Employees

Employees should be made clear for the need of adopting six sigma and the benefits of it.

The roles of every employees in the deployment and that of the project lead should be made clear. The expected outcome of the project should also be highlighted.

Quality aspects for the change should be emphasized like for example, customer quality expectations and current level of performance to those expectations.

Financial benefit for the company can also be explained and the need for improving the value proposition.

The metrics used to measure the project’s success should be briefed. The focus should be laid on improving quality.

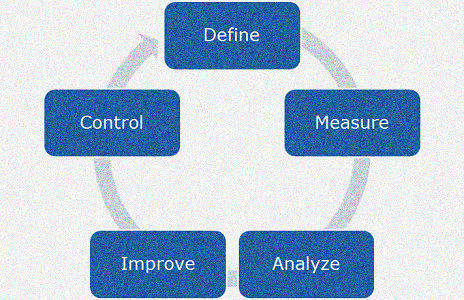

Methodology for Six Sigma

Define

The problems have to be defined clearly like for example, what is the goal that needs to be achieved, customer expectations etc... This can be achieved using the following:

- Customers, Value, Problem Statement

- Scope, Timeline, Team

- Primary / Secondary & Operational Excellence Metrics

Define techniques:

Current Value Stream Map

Flowchart drawn to visualize the process and to track performance. This helps to find out which step add value and which do not

Quality Function Deployment (QFD)

It is a method of prioritizing the customer’s requirements as specified by the customers. Translate them into process requirements and target to achieve them

Measure

We need to measure the key parameters for the current process in place and collect the relevant data. Various parameters which can be measured are:

Business Impact

- Revenue

- Cost Reduction

- Business Objectives

- On Time Delivery

- Lead Time

- Quality

- Customer Satisfaction

Impact on Operational Excellence Metrics

Effort required - People, Capital, Duration of Project

Probability of success

Analyze

Analyse the data to determine the relationships and attempt to ensure that all factors have been considered. This will help to find the root cause of the defect or problem.

Find all KPOVs (Key Process Output Variables) & KPIVs (Key Process Input Variables).

Analysis techniques:

FMEA (Failure Modes Effects Analysis)

Helps in analysis of potential failure modes within a system (classifying under severity and likelihood of the failures)

DOE (Design Of Experiment)

Used to test cause-and-effect relationships between variables

ANOVA (Analysis Of Variance)

Used to identify factors that are influencing a given data set

Future Value Stream Map

Flowchart drawn to visualize the future state of the process and the state where which we want to achieve

Improve

Based on the data analysis we can improve or optimize the current process. Pilot runs can be used to establish process capability.

Optimize KPOVs (Key Process Output Variables) & test the KPIVs (Key Process Input Variables), Redesign process and Value Stream Plan.

Control

Control the future state process so that there is no deviations from the target and monitor the process so that the desired results are yielded every time.

Managing the established process is very critical for long term success. This responsibility has to be owned by project champion and value stream manager

Measurement controls over on-going metrics

Visual Controls will enable workers to self-manage the process

This article should have helped you to understand Six Sigma. Six Sigma provides quality improvements to Software companies and projects also. Good luck implementing Six Sigma!